Ball Valves in Oil and Gas Pipelines: Uses and Advantages

When it comes to oil and natural gas transportation, safety, reliability, and efficiency are non-negotiable. At the heart of many pipeline systems lies the ball valve — a simple yet highly effective device that has become an industry standard. Ball valves are known for their durability, quick operation, and excellent sealing performance, making them essential for both upstream and downstream operations.

In this article, we will take a deep dive into how ball valves work, why they are favored in the oil and gas sector, and what operators should know about their advantages, operational practices, and common issues.

What Is a Ball Valve?

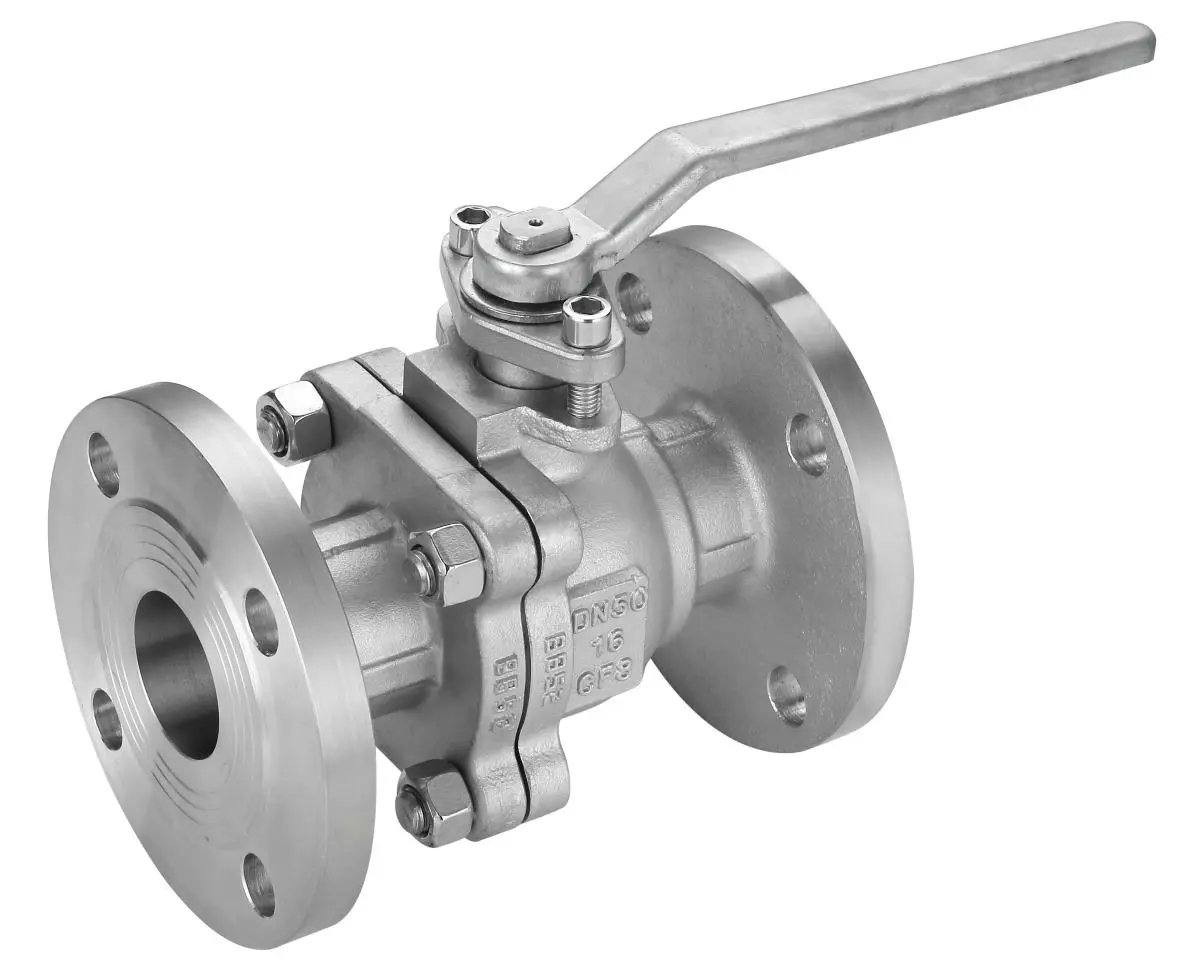

A ball valve is a type of quarter-turn valve that uses a spherical closure unit (the “ball”) with a central bore to control the flow of fluids or gases. When the valve handle is turned 90 degrees, the bore aligns with the pipeline to allow flow, or it rotates perpendicular to block the flow completely.

Ball valves were developed from Plug Valves, but instead of a cylindrical plug, they use a spherical one, reducing wear and improving sealing. The design ensures minimal fluid resistance, easy operation, and reliable performance under demanding conditions.

Key features of a ball valve include:

- Quarter-turn operation: Fully open or closed with just a 90° rotation.

- Tight sealing: Ensures minimal leakage even under high pressure.

- Versatility: Can handle liquids, gases, and even corrosive or high-temperature media.

How Ball Valves Work in Pipelines

The principle of operation is simple but effective. Inside the valve body, the spherical ball has a bore (hole) through its center.

Open position: When the bore is aligned with the pipeline, the fluid flows freely.

Closed position: A 90° turn rotates the ball, presenting the solid side to the flow path, blocking the medium completely.

Because the sealing surfaces of the ball and valve seat remain in contact when closed, the valve resists erosion and maintains a strong seal even after years of operation.

For oil and gas pipelines, where long-distance transport and high pressures are common, this reliable shut-off ability is critical to preventing leaks and ensuring operational safety.

Why Ball Valves Are Widely Used in Oil and Gas

The oil and gas industry requires valves that can withstand harsh environments, high pressures, and variable flow conditions. Ball valves meet these challenges with several clear advantages:

(a) Low Flow Resistance

Ball valves provide almost no pressure drop because of their straight-through flow path. This helps maintain efficiency in long-distance crude oil or natural gas transmission.

(b) Compact and Lightweight

Compared to gate or globe valves, ball valves are smaller and easier to install, an important factor for offshore platforms or compact pipeline stations.

(c) Tight and Reliable Sealing

Modern ball valves often use resilient seat materials (such as PTFE or high-performance polymers), which offer excellent sealing performance. Even in vacuum systems, ball valves maintain tight shut-off.

(d) Easy Operation

Because they only require a quarter-turn, ball valves are fast to operate and can be automated for remote control. In large oil and gas networks, this feature supports safety systems and emergency shut-down procedures.

(e) Wide Application Range

Ball valves can be manufactured in sizes ranging from a few millimeters to several meters in diameter. They are used in gathering lines, transmission pipelines, processing facilities, and even LNG terminals.

Operational Guidelines for Ball Valves

Despite their simple design, ball valves must be operated correctly to ensure long service life. Key practices include:

- Understand technical parameters: Operators should be familiar with the valve’s pressure and temperature limits before use.

- Pre-operation checks: Pipelines and valves must be cleaned before operation to prevent debris from damaging the sealing surfaces.

- Correct operation direction: Typically, clockwise rotation closes the valve, while counterclockwise rotation opens it. The valve’s position is indicated by the alignment of the handle with the pipeline.

- Avoid excessive force: Ball valves are designed for smooth quarter-turn operation. Using force or tools can damage the stem or actuator.

- Use for shut-off only: Ball valves are primarily designed for isolation, not for throttling flow. Using them as throttling devices can damage seats and cause leaks.

Common Failures and Troubleshooting

Even robust ball valves can encounter issues, particularly in the demanding environment of oil and gas pipelines. The most common problems include:

(a) Seat Leakage

Cause: Debris such as sand, welding residue, or corrosion products stuck between the ball and seat.

Prevention: Regular cleaning, proper filtration, and correct pipeline flushing before operation.

(b) Seal Damage

Cause: Scratches or corrosion on the ball or seat sealing surfaces, often due to abrasive particles.

Solution: Replace damaged seals and ensure proper pigging (pipeline cleaning) operations.

(c) Stuck Seats

Cause: Faulty springs or accumulation of hardened materials can prevent the seat from moving freely.

Solution: Regular lubrication and maintenance checks.

(d) Stem or Actuator Misalignment

Cause: Wear or improper installation may cause incomplete opening or closing.

Solution: Ensure proper alignment during installation and inspect actuators regularly.

(e) Corrosion

Cause: Aggressive media such as sour gas (H₂S) or high salinity water.

Solution: Select corrosion-resistant materials (e.g., stainless steel, Inconel) for valve construction.

Maintenance Practices

Good maintenance is the key to extending valve life and ensuring safety in oil and gas systems. Recommended practices include:

- Routine inspection: Check for leaks, unusual noises, or difficulty in operation.

- Lubrication: Apply valve-specific greases to reduce wear and prevent corrosion.

- Seal replacement: Replace worn or aged seals during scheduled shutdowns.

- Actuator servicing: Ensure actuators and control systems remain responsive and calibrated.

- Material selection: For corrosive environments, always select materials designed to resist chemical attack.

The Future of Ball Valves in Oil and Gas

With the rise of automation and digital monitoring, ball valves are increasingly integrated into smart pipeline systems. Remote operation, predictive maintenance, and IoT-enabled monitoring are becoming standard. This not only improves safety but also optimizes operational efficiency.

Additionally, as the industry transitions toward hydrogen and carbon capture pipelines, ball valve designs are evolving to handle new challenges, such as higher hydrogen permeability and CO₂ corrosion resistance.

Conclusion

Ball valves may look simple, but their impact on the oil and gas industry is massive. Their ability to provide tight shut-off, low resistance, and fast operation makes them a cornerstone of modern pipeline infrastructure. By following proper operational practices and maintaining valves regularly, operators can maximize safety, efficiency, and service life.

From long transmission pipelines to LNG terminals, ball valves continue to prove why they are the go-to choice for oil and natural gas applications