NDT Methods

Scope of metal flaw detection:

Surface defects in welds, lack of fusion and incomplete fusion, internal surface cracks, scaling, wire marks, scratches, pits, protrusions, spots, corrosion, residual internal chips, foreign matter, etc.

Metal Non-Destructive Testing Items:

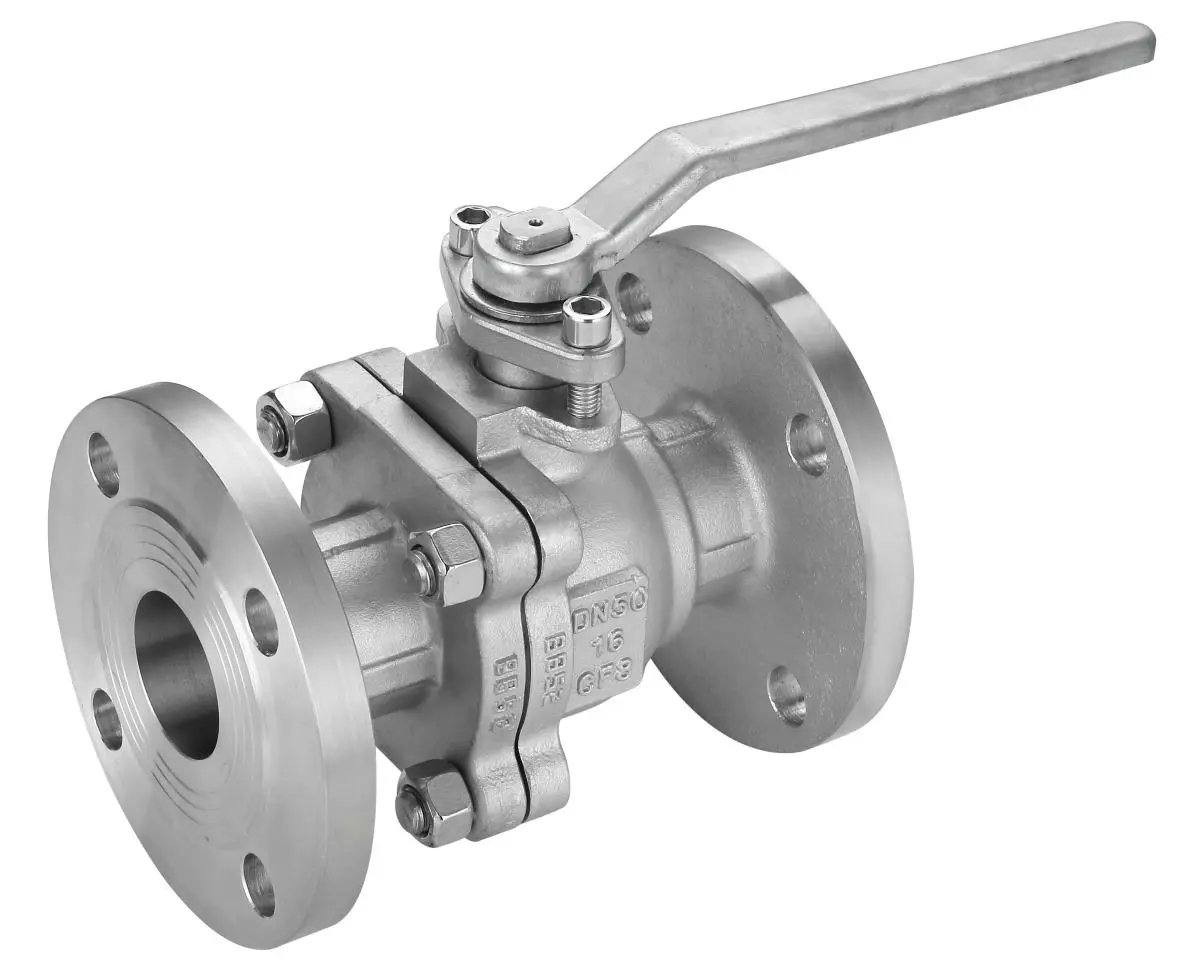

Various types of metallic materials and metal products, including metal castings.

Methods for metal flaw detection:

1、Radiographic Testing (RT)

Radiographic testing is a method that employs radiation to inspect internal defects within welds. The most commonly used types of radiation are X-rays and gamma rays. Capturing “photographs” of the interior of metals, providing a visual representation of the two-dimensional shape and distribution of three-dimensional defects such as porosity, shrinkage cavities, and slag inclusions.

2.Magnetic Particle Testing (MT)

Magnetic particle testing is a method employing magnetic particles as a visualising medium to observe defects. Depending on the type of magnetic particle medium applied during magnetisation, the inspection method is categorised as either the wet method or the dry method; based on the duration for which the magnetic particles remain applied to the workpiece, it is classified as either the continuous method or the residual magnetism method.Rapidly detect linear defects such as fine cracks and folds on the surface and near-surface of ferromagnetic materials (e.g., steel, iron).

3.Ultrasonic Testing (UT)

Ultrasonic testing is a method that employs ultrasonic waves to inspect internal defects within metallic components. It detects internal flaws by analysing the time difference between the transmission and reception of reflected signals at the probe.Detect internal defects within materials such as cracks, lack of fusion, and slag inclusions, whilst precisely measuring their location and dimensions. It can also accurately measure thickness.

4.Liquid Penetrant Testing (PT)

Liquid penetrant testing, also known as penetrant inspection, is a non-destructive testing method for detecting surface-opening defects based on the principle of capillary action.Detect all surface-breaking defects (such as cracks and porosity) in non-porous metallic materials, regardless of whether they are magnetic.

Inspector from BUREAU VERITAS come to NST valve carry out PT testing on SS316 disc.