Seawater Desalination Guide: How to Choose Anti-Corrosion Valves

Seawater desalination has become an increasingly important solution in regions facing fresh-water shortages. In recent years, large-scale desalination projects have been built across the Middle East, North Africa and coastal parts of Asia in order to secure a stable supply of potable water. From a technical point of view, one of the most critical topics in these projects is valve selection — especially when it comes to anti-corrosion performance.

Once seawater enters the pretreatment stage, most piping components come into prolonged contact with highly saline, corrosive media. Compared with fresh water, seawater contains higher concentrations of chloride ions, which cause serious pitting and crevice corrosion. Choosing the wrong valve can lead to leaks, sudden failure or constant replacement costs. This is why engineers must evaluate not only flow control performance, but also corrosion resistance, durability and long-term O\&M considerations.

So how do we select the right anti-corrosion valve for a seawater desalination plant? The answer depends on four key aspects: the type of desalination process, the media conditions, the valve body material, and the coating/lining technology. Below you’ll find a practical guide on how to evaluate these factors.

Identify the Desalination Stage and Operating Conditions

In a typical seawater desalination plant, there are three major stages: pretreatment, reverse osmosis (RO) and post-treatment. The valve requirements of each stage are different:

1.Pretreatment stage

This stage involves coarse filtration, fine filtration and chemical conditioning. Valves are exposed to raw seawater, which has a high chloride ion concentration and often contains biological contaminants and suspended solids. Components must therefore resist abrasion and biological fouling in addition to regular corrosion.

2.Reverse osmosis stage

In RO modules, the operating pressure can reach 60–80 bar. The brine becomes even more concentrated, and valves need to endure high pressure and high salinity at the same time. Any failure in this section can cause severe downtime.

3.Post-treatment stage

Treated water often needs chemical re-mineralization or disinfection with chlorine. Although the salinity is reduced, chemical resistance becomes more relevant, especially when dosing systems are involved.

At the very beginning of valve selection, you should define the actual medium (seawater, brine or chemical solution), the pressure range, and the fluid temperature. Without this information, you can hardly select the correct material or valve type.

Choose the Right Valve Body Material

Valve corrosion resistance is largely determined by the base material. The following are commonly used in desalination projects:

| Material | Characteristics and Suitability |

| Duplex Stainless Steel (e.g. 2205) | Strong chloride corrosion resistance;good choice for pretreatment and RO systems; widely used in seawater environments. |

| Super Duplex (e.g. 2507) | Even higher pitting resistance; suitable for high-pressure brine service; high cost but long service life. |

| Nickel-Aluminium Bronze | Excellent seawater resistance; good mechanical strength; widely used for seawater pumps and pipeline valves. |

| Monel (nickel-copper) | Highly resistant to salt water and caustic solutions; mainly used in aggressive applications; higher price. |

| Titanium | Outstanding corrosion resistance even in highly concentrated brine; low weight; ideal for critical RO valves but extremely expensive. |

| PVC / CPVC / FRP | Economical options for low-pressure service and chemical dosing; not suitable for high-pressure RO lines. |

You don’t always need the most expensive material. For example, duplex stainless steel often provides a very balanced combination of price and performance. Titanium or nickel alloys are usually reserved for the most corrosive conditions where normal stainless steel might fail rapidly.

Pay Attention to Internal Coating and Lining

In many desalination applications, the media does not only attack the outer body, but also the internal surfaces, especially near sealing areas. That’s why internal coating is vital. Common lining/coating options include:

- Fusion-bonded epoxy (FBE)– a cost-effective protection for internal surfaces in pre-treatment systems.

- PTFE lining – excellent chemical resistance; suitable for dosing sections after RO.

- Rubber lining– useful for abrasion resistance when dealing with suspended solids.

- Glass flake coatings– provide barrier protection when combined with stainless steel.

A frequently overlooked detail is the bond strength between the coating and the metal surface. Poor surface preparation or low-quality coatings can cause blistering and local corrosion underneath the lining.

Tip: If the coating breaks or peels, even a high-grade stainless steel valve can corrode quickly. Always check the coating specification and application procedure.

Select the Appropriate Valve Type

Different valve types offer different advantages in seawater service. Here’s a short summary:

| Valve Type | Remarks (in seawater service) |

| Butterfly Valve | Lightweight, simple structure and low cost; commonly used in intake and pre-treatment systems; needs rubber-lined or duplex disc for seawater. |

| Gate Valve | Good for isolation in low-pressure sections; can be supplied in duplex or bronze; not ideal in systems with high differential pressure. |

| Globe Valve | Precise flow control; often used in dosing or control loops; seals must have excellent corrosion resistance. |

| Check Valve | Prevent backflow in RO and pump discharge lines; swing or tilt-disc type with duplex body is recommended. |

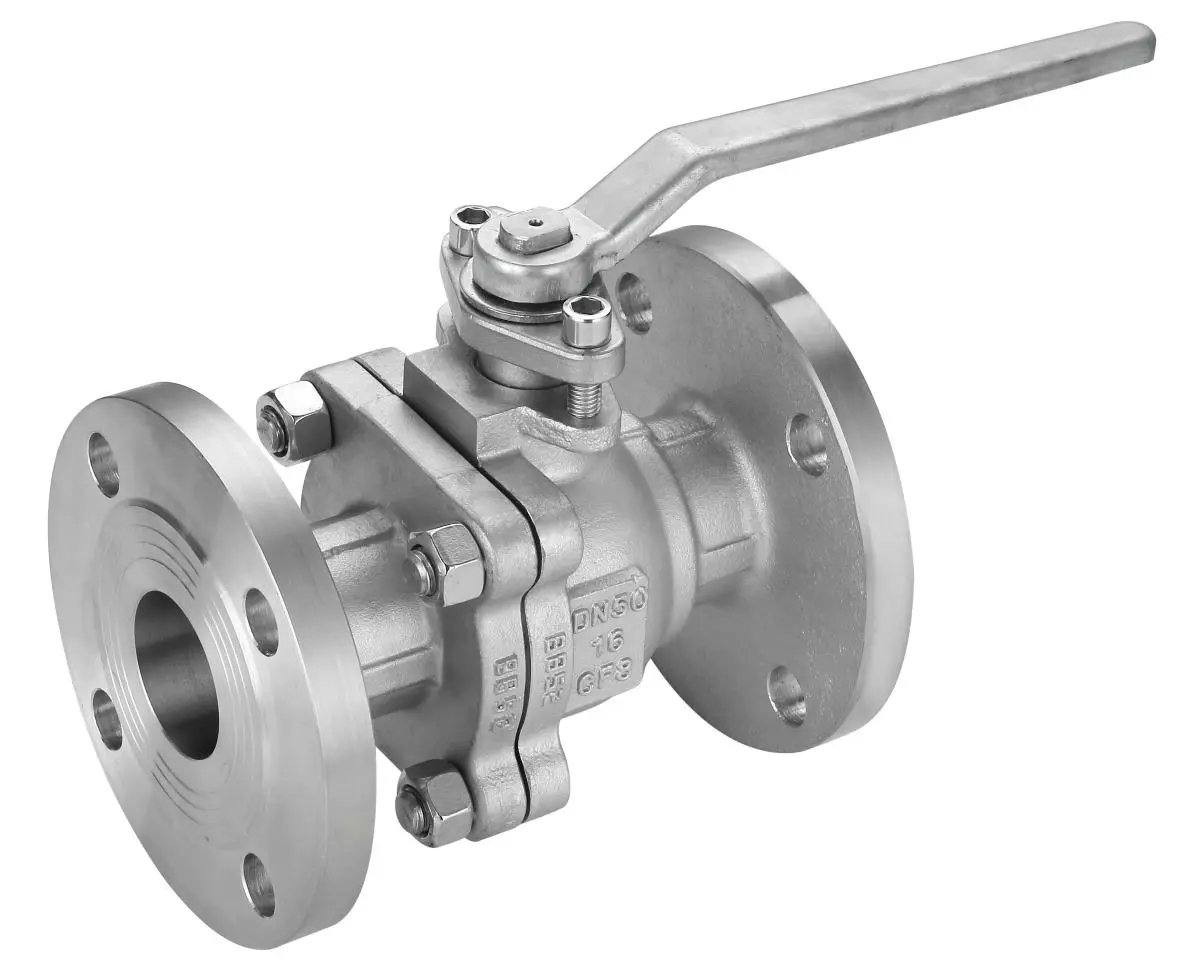

| Ball Valve | High sealing performance and durability; suitable for high-pressure RO systems; must use duplex or titanium seat and ball. |

In RO systems, high-pressure ball valves with super-duplex construction are commonly selected because they maintain tight shut-off at high pressures and have low torque.

Evaluate Long-Term Maintenance and Total Cost of Ownership

Many project owners focus purely on initial purchase price, but the total cost of ownership can be much higher if a valve fails prematurely. These costs include:

- Valve replacement

- Plant downtime

- Labor for disassembly and re-assembly

- Water loss / production interruption

- Recoating or relining costs

That’s why it’s important to analyze maintenance intervals, the availability of spare parts, and the life expectancy of the selected material.

For example, a super duplex valve might cost 30–40% more than a standard duplex valve, but if it doubles the service life in the RO section, it usually results in a lower total life-cycle cost.

Confirm Compliance with Industry Standards

Make sure the selected valves comply with standards that apply to seawater desalination:

| Standard | Description |

| ISO 21457 | Corrosion protection of piping materials used in petroleum and natural gas installation in seawater environments (widely referenced by desalination designers). |

| ASTM G48 | Pitting and crevice corrosion tests for stainless steels and related alloys. |

| EN 12516 | Pressure/temperature rating of Industrial Valves. |

In international bidding documents, many EPC contractors specify materials according to ISO 21457 or similar offshore standards. Confirming material test certificates ensures that the valve can actually meet these requirements and is not just “stainless steel” in name.

Conclusion – Combine Material, Function and Long-Term Perspective

To sum up, there is no single valve that fits all seawater desalination services. The optimal anti-corrosion solution depends on:

- The exact process stage (raw seawater vs concentrated brine)

- The expected pressure and temperature levels

- The specific corrosion risks (chlorides, chemicals, abrasion)

- And the long-term maintenance strategy of your plant

Material selection and coating strategy should always be considered together with valve type and actual operating conditions. For high-pressure RO systems, super duplex or titanium ball valves might be necessary. For low-pressure pre-treatment lines, duplex Butterfly Valves with internal epoxy coating can offer an excellent cost-performance ratio.

By evaluating the media conditions, choosing the right body material, applying proper internal protection and selecting the suitable valve type, engineers can effectively reduce corrosion-related failure and increase the reliability of seawater desalination systems.