Bi-Directional Zero Leakage Tilting Disc Check Valve

Production description

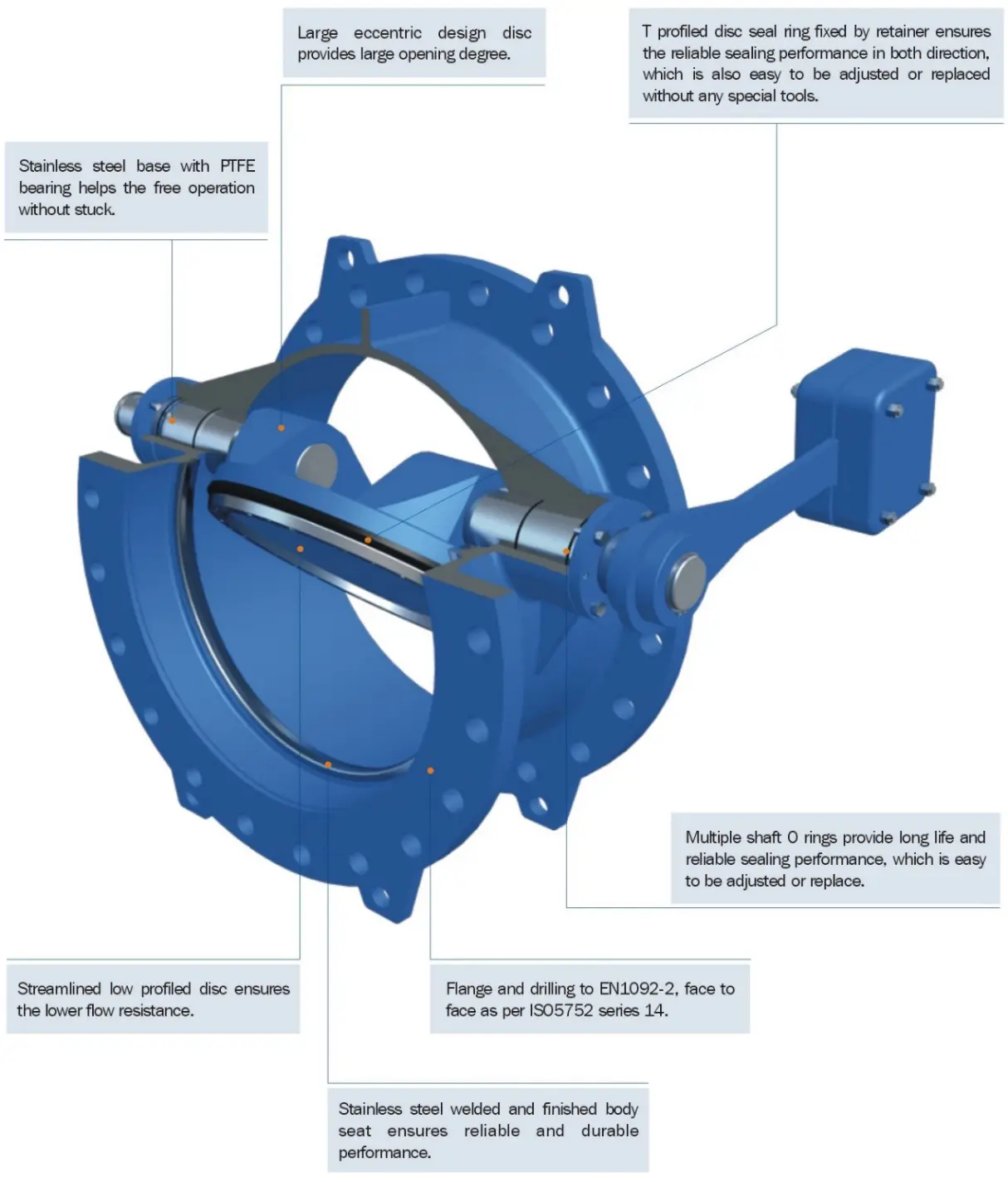

Valve design to EN593, EN 12334

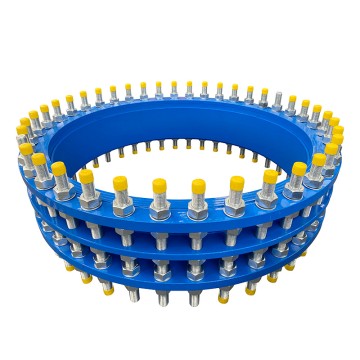

Flange to EN 1092, BS4504, DIN2501, ISO7005, ASME B16.5, ASME B16.1, AWWA C207, AS4087

Face to face length to EN 558-1 / ISO 5752 series 14

♦ The tilting disc conserves energy and provides the lowest operating cost because of no need external power pack/power unit.

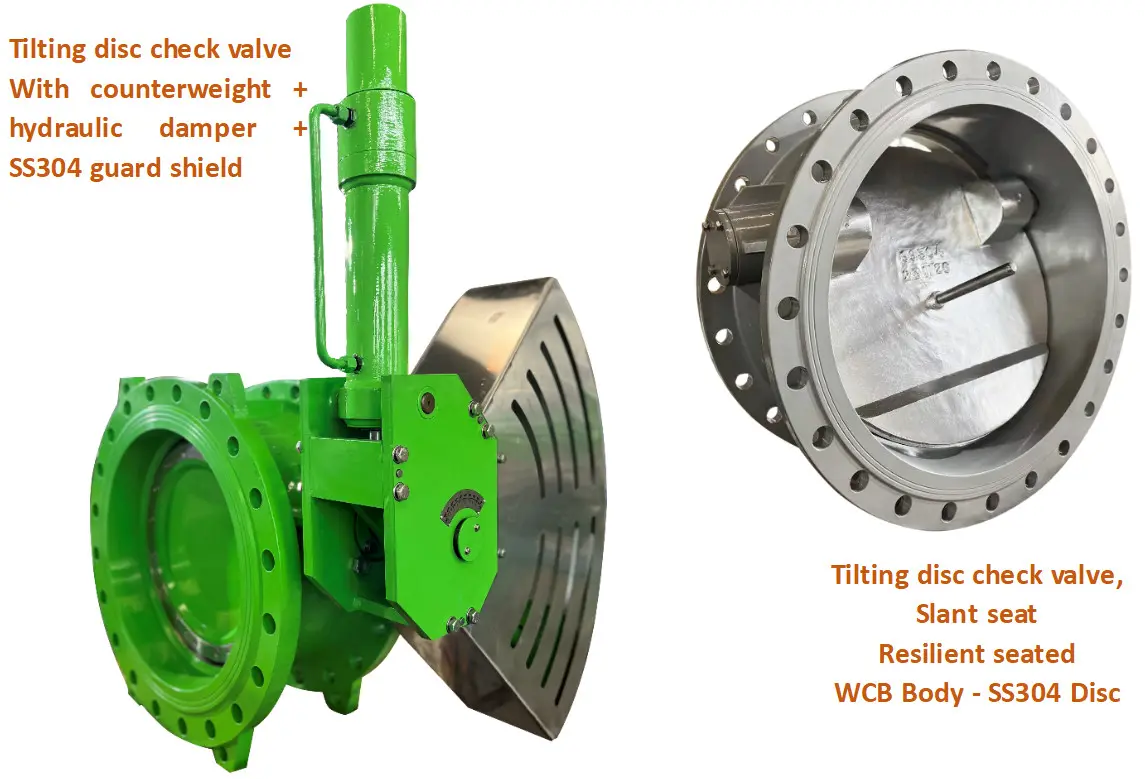

♦ The large offset design and disc self-containing weight at the bottom of valve disc make the disc closing rapidly to minimize flow reversal and water hammer normally associated with the sudden stopping of a reverse flow.

Meanwhile the large offset design results in valve disc divided into approximately a one third and a two thirds proportion. This allows the two thirds of flow passing below the shaft to be counteracted by the one third flow passing above the shaft. This counteraction reduces slamming by providing a self-cushioning effect.

♦ The external counterweight attached to the valve by a lever will be designed to assist valve closing. And the counterweight position could be adjusted along the axial direction of lever to accommodate to on-site working conditions.

♦ Stainless steel weld and finished body seat ensures reliable and durable performance in leak tight seating.

♦ Streamlined body and low profiled disc design verified by finite element analysis ensures the higher strength and the low head loss.

♦ Self-lubricating bearing in bronze or stainless steel lined PTFE helps the free operation without stuck.

♦ T profiled resilient seal ring is secured on the disc by a retainer ring and bolts, and ensures reliable performance. The seal ring could be adjusted or replaced easily on site. Don’t need special tools.

♦ Multiple O rings in shaft sealing system provide long life and reliable sealing performance, which is easy to be adjusted or replaced.

♦ Valve externally and internally fusion bonded epoxy coated with a thickness of 250micron (different coating/lining is available when specified) and color code RAL5005/5015/5017.

● Optional design to improve features and operating characteristics

● Slant seat design: it provides short disc stroke to have a better non-return performance and reduces water hammer.

● Limit switch: Mechanical or proximity type limit switches are available for disc position reading out on remote panel and/or secondary system operations.

● Position indicator: Disc position indicator on valve

● Hydraulic damper/oil dashpot will be designed for some critical conditions, such as high shut-off heads, use pressure tanks or surge tanks, to further reduce the water hammer caused by rapid flow reversal.

● The guard shield for counterweight can be supplied when specified.

● Extended shaft ends at both sides will be convenient to exchange counterweight position according to on-site installation requirements.

TILTING DISC CHECK VALVE

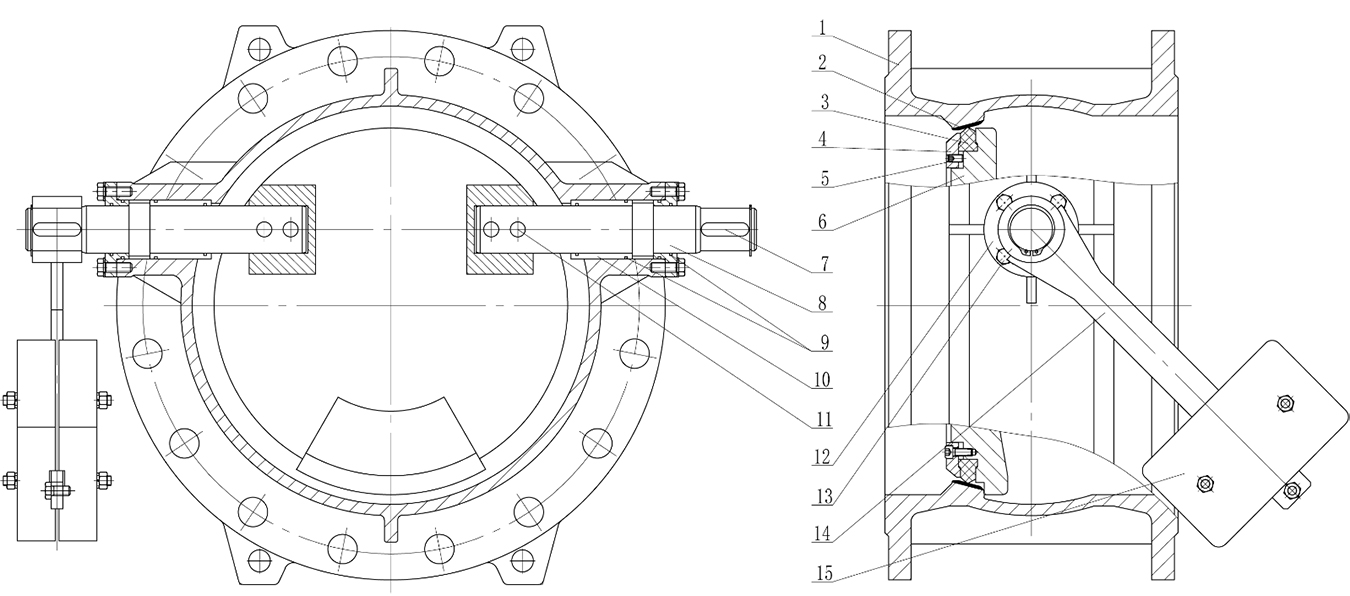

Materials of component

|

No |

NAME |

MATERIAL* |

SPECIFICATION |

REMARKS |

|

1 |

Valve Body |

Ductile Iron |

GJS500-7(GGG50), GJS400-15(GGG40) 65-45-12, 60-40-18 |

|

|

Carbon steel |

1.0619(WCB) |

|||

|

2 |

Body Seat |

Stainless Steel |

Cr-Ni alloy / Ni welded |

|

|

3 |

Disc Seal Ring |

Rubber |

EPDM, NBR, FKM, Silastic |

|

|

4 |

Retainer Ring |

Carbon Steel |

1.0038(S235JR) |

|

|

Stainless Steel |

1.4301(SS304), 1.4401(SS316),1.4571(SS316Ti) |

|||

|

5 |

Screw |

Stainless Steel |

A2-70(SS304), A4-70(SS316) |

|

|

6 |

Valve Disc |

Ductile Iron |

GJS500-7(GGG50), GJS400-15(GGG40) 65-45-12, 60-40-18 |

|

|

Carbon steel |

1.0619(WCB) |

|||

|

7 |

Key |

Stainless Steel |

1.4021(SS420) |

|

|

8 |

Valve Shaft |

Stainless Steel |

1.4021(SS420), 1.4057(SS431),17-4PH(SS630) |

|

|

Duplex Stainless Steel |

1.4462(S31803),1.4507(S32750) |

|||

|

9 |

0 ring |

Rubber |

EPDM, NBR |

|

|

10 |

Shaft Bearing |

Bronze |

QAI9-2 CC331G |

|

|

11 |

Pin |

Stainless Steel |

1.4021(SS420), 1.4057(SS431),17-4PH(SS630) |

|

|

Duplex Stainless Steel |

1.4462(S31803), 1.4507(S32750) |

|||

|

12 |

Shaft Cover |

Carbon Steel |

1.0038(S235JR) |

|

|

Stainless Steel |

1.4301(SS304), 1.4401(SS316) |

|||

|

13 |

Bolt |

Stainless Steel |

A2-70(SS304), A4-70(SS316) |

|

|

14 |

Lever |

Carbon Steel |

1.0038(S235JR) |

|

|

15 |

Counterweight |

Carbon Steel |

1.0038(S235JR) |

(Other materials are available on request.)

Coating: fusion bonded epoxy coating, min. thickness 300 micron

Suitable medium: potable water, drinking water, sea water, TSE water, low-corrosive liquid etc.

Suitable temperature: 0 ~ 80 ℃

Pressure test to EN12266-1: Leakage rate: Class A (Zero leakage)

100% testing before delivery

TILTING DISC CHECK VALVE

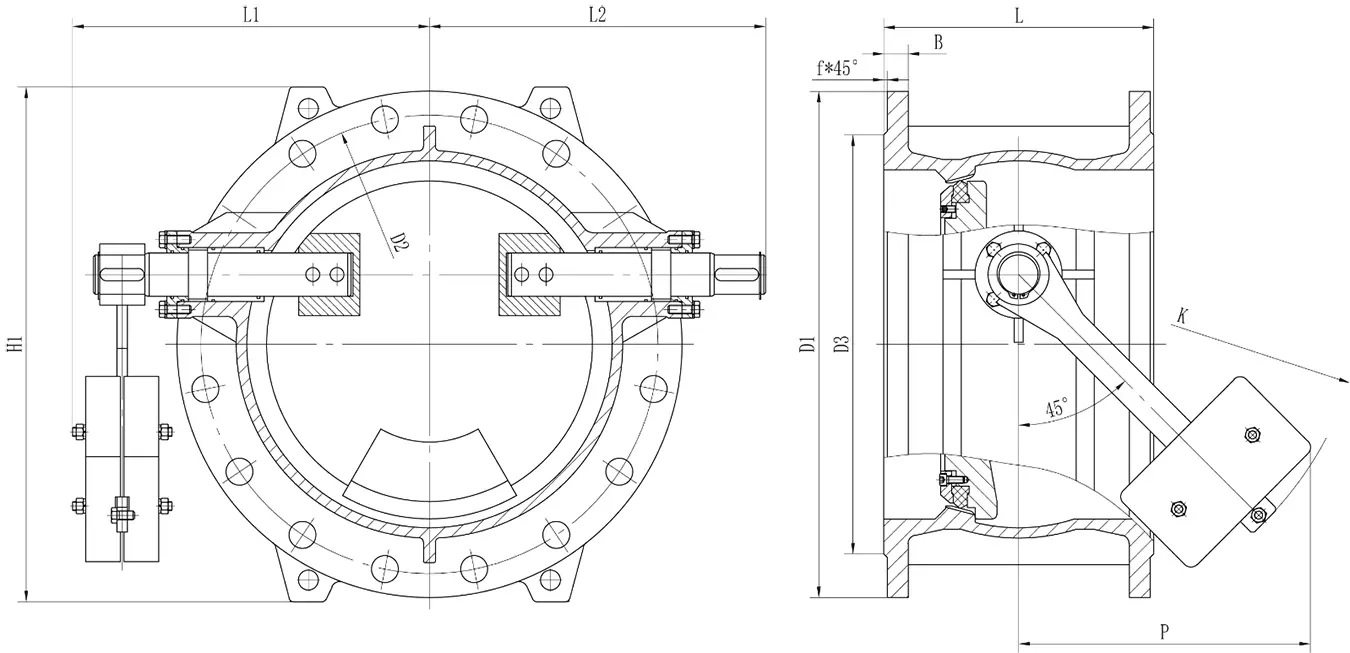

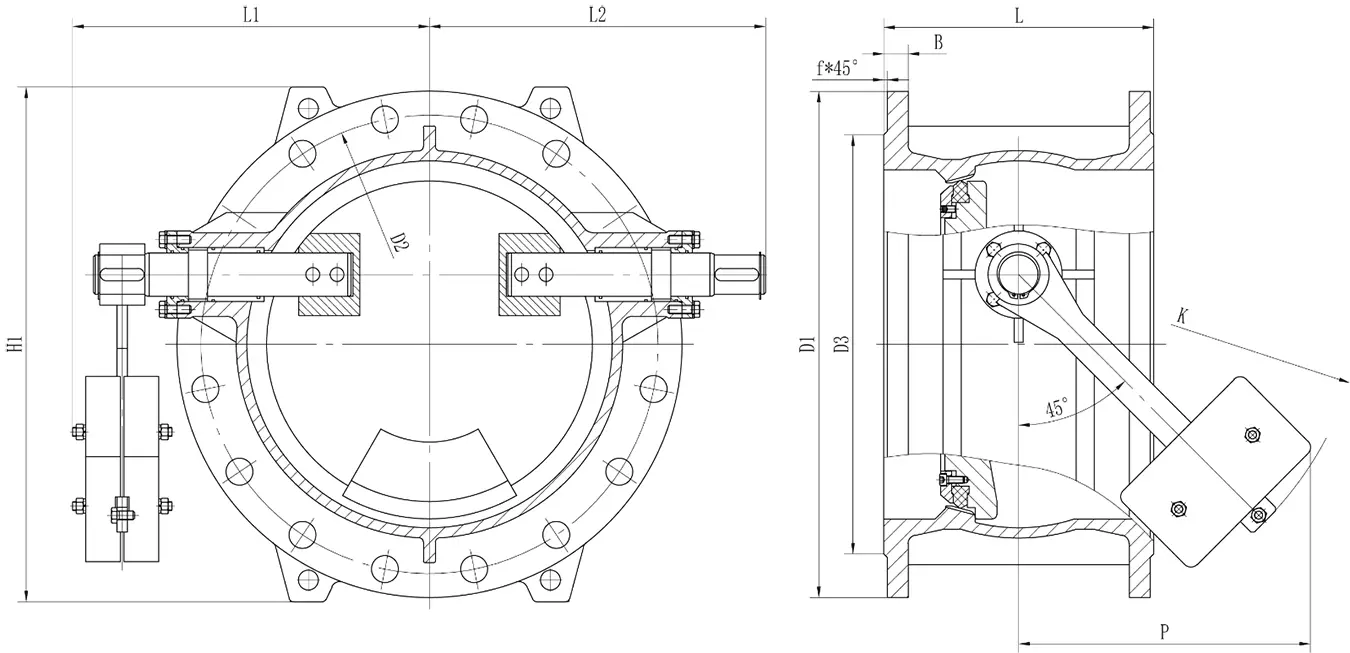

Dimensions*/PN10

|

DN |

D1 |

D2 |

D3 |

B |

f |

L |

n-d |

H1 |

L1 |

L2 |

P |

K |

Weight kgs |

|

200 |

Φ340 |

Φ295 |

Φ266 |

20 |

3 |

230 |

8-Φ23 |

350 |

235 |

230 |

180 |

200 |

50 |

|

250 |

Φ405 |

Φ350 |

Φ319 |

22 |

3 |

250 |

12-Φ23 |

415 |

280 |

270 |

210 |

250 |

80 |

|

300 |

Φ460 |

Φ400 |

Φ370 |

24.5 |

4 |

270 |

12-Φ23 |

470 |

320 |

310 |

250 |

300 |

100 |

|

350 |

Φ520 |

Φ460 |

Φ429 |

26.5 |

4 |

290 |

16-Φ23 |

530 |

370 |

350 |

300 |

350 |

150 |

|

400 |

Φ580 |

Φ515 |

Φ480 |

28 |

4 |

310 |

16-Φ28 |

590 |

410 |

385 |

340 |

400 |

190 |

|

450 |

Φ640 |

Φ565 |

Φ530 |

30 |

4 |

330 |

20-Φ28 |

650 |

460 |

435 |

370 |

450 |

265 |

|

500 |

Φ715 |

Φ620 |

Φ582 |

31.5 |

4 |

350 |

20-Φ28 |

725 |

520 |

490 |

420 |

500 |

320 |

|

600 |

Φ780 |

Φ725 |

Φ682 |

30 |

5 |

390 |

20-Φ31 |

790 |

550 |

520 |

490 |

600 |

400 |

|

700 |

Φ895 |

Φ840 |

Φ794 |

32.5 |

5 |

430 |

24-Φ31 |

905 |

620 |

485 |

560 |

700 |

550 |

|

800 |

Φ1015 |

Φ950 |

Φ901 |

35 |

5 |

470 |

24-Φ34 |

1025 |

690 |

665 |

650 |

800 |

780 |

|

900 |

Φ1115 |

Φ1050 |

Φ1001 |

37.5 |

5 |

510 |

28-Φ34 |

1125 |

770 |

735 |

720 |

900 |

1050 |

|

1000 |

Φ1230 |

Φ1160 |

Φ1112 |

40 |

5 |

550 |

28-Φ37 |

1240 |

860 |

820 |

790 |

1000 |

1400 |

|

1200 |

Φ1455 |

Φ1380 |

Φ1328 |

45 |

5 |

630 |

32-Φ41 |

1465 |

990 |

950 |

850 |

1200 |

2200 |

|

1400 |

Φ1675 |

Φ1590 |

Φ1530 |

46 |

5 |

710 |

36-Φ44 |

1690 |

1180 |

1080 |

960 |

1300 |

3100 |

|

1600 |

Φ1915 |

Φ1820 |

Φ1750 |

49 |

5 |

790 |

40-Φ50 |

1930 |

1460 |

1380 |

1050 |

1400 |

4800 |

*

-Flange dimensions and drilling to BS EN 1092-2 PN10

-All the outline dimensions and weight only for reference. If need, please contact us for exact data.

-Please contact us for other details or larger sizes.

Dimensions*/PN16

|

DN |

D1 |

D2 |

D3 |

B |

f |

L |

n-d |

H1 |

L1 |

L2 |

P |

K |

Weight kgs |

|

200 |

Φ340 |

Φ295 |

Φ266 |

20 |

3 |

230 |

12-Φ23 |

350 |

235 |

230 |

180 |

200 |

50 |

|

250 |

Φ405 |

Φ355 |

Φ319 |

22 |

3 |

250 |

12-Φ28 |

415 |

280 |

270 |

210 |

250 |

80 |

|

300 |

Φ460 |

Φ410 |

Φ370 |

24.5 |

4 |

270 |

12-Φ28 |

470 |

320 |

310 |

250 |

300 |

100 |

|

350 |

Φ520 |

Φ470 |

Φ429 |

26.5 |

4 |

290 |

16-Φ28 |

530 |

370 |

350 |

300 |

350 |

150 |

|

400 |

Φ580 |

Φ525 |

Φ480 |

28 |

4 |

310 |

16-Φ31 |

590 |

410 |

385 |

340 |

400 |

190 |

|

450 |

Φ640 |

Φ585 |

Φ548 |

30 |

4 |

330 |

20-Φ31 |

650 |

460 |

435 |

370 |

450 |

265 |

|

500 |

Φ715 |

Φ650 |

Φ609 |

31.5 |

4 |

350 |

20-Φ34 |

725 |

520 |

490 |

420 |

500 |

320 |

|

600 |

Φ840 |

Φ770 |

Φ720 |

36 |

5 |

390 |

20-Φ37 |

850 |

580 |

540 |

490 |

600 |

435 |

|

700 |

Φ910 |

Φ840 |

Φ794 |

39.5 |

5 |

430 |

24-Φ37 |

920 |

645 |

600 |

560 |

700 |

600 |

|

800 |

Φ1025 |

Φ950 |

Φ901 |

43 |

5 |

470 |

24-Φ41 |

1035 |

710 |

690 |

650 |

800 |

820 |

|

900 |

Φ1125 |

Φ1050 |

Φ1001 |

46.5 |

5 |

510 |

28-Φ41 |

1135 |

800 |

760 |

720 |

900 |

1150 |

|

1000 |

Φ1255 |

Φ1170 |

Φ1112 |

50 |

5 |

550 |

28-Φ44 |

1265 |

890 |

840 |

790 |

1000 |

1500 |

|

1200 |

Φ1485 |

Φ1390 |

Φ1328 |

57 |

5 |

630 |

32-Φ50 |

1500 |

1030 |

980 |

850 |

1200 |

2400 |

|

1400 |

Φ1685 |

Φ1590 |

Φ1530 |

60 |

5 |

710 |

36-Φ50 |

1700 |

1280 |

1160 |

960 |

1300 |

3350 |

|

1600 |

Φ1930 |

Φ1820 |

Φ1750 |

65 |

5 |

790 |

40-Φ57 |

1945 |

1560 |

1450 |

1050 |

1400 |

5100 |

*

-Flange dimensions and drilling to BS EN 1092-2 PN16

-All the outline dimensions and weight only for reference. If need, please contact us for exact data.

-Please contact us for other details or larger sizes.

product display