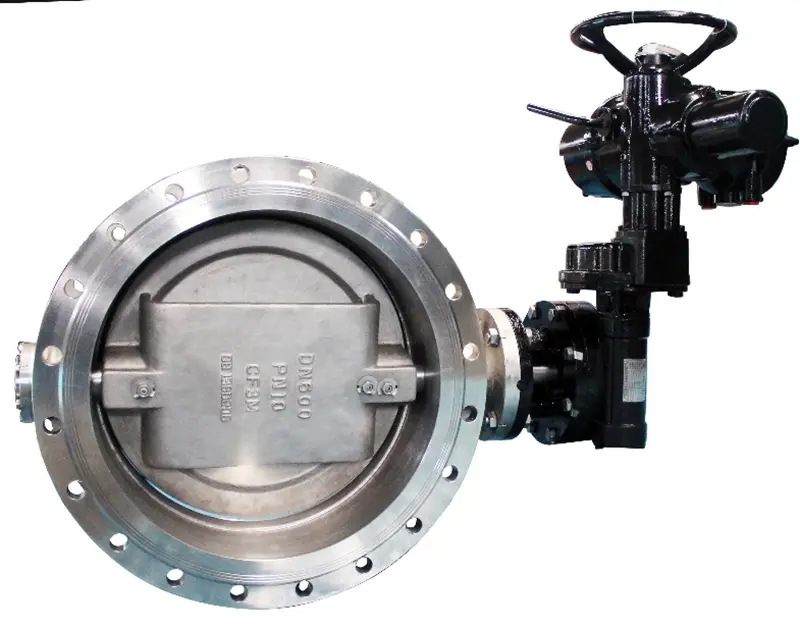

Triple Eccentric Metal Seated Butterfly Valve

Product description

Valve design to EN 593, API 609, ASME B16.34, BS5155

Flange to EN 1092, ASME B16.5, ASME B 16.47, AWWA C207, API 605

Face to face length to EN 558-1 / ISO 5752 series 13, API 609

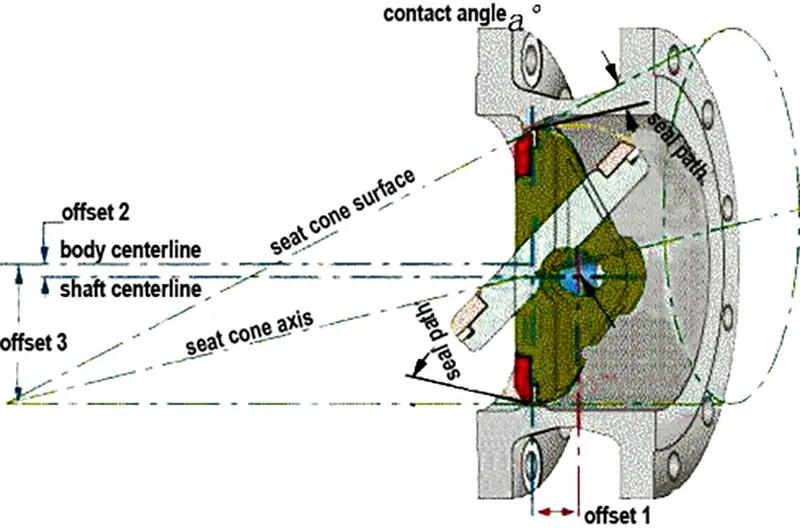

-- Tight shut-off and control with metal to metal seal

-- Triple offset design, No friction with seat during the full travel operation.

-- Torque sealing instead of position sealing to achieve bi - directional sealing with long - term stability.

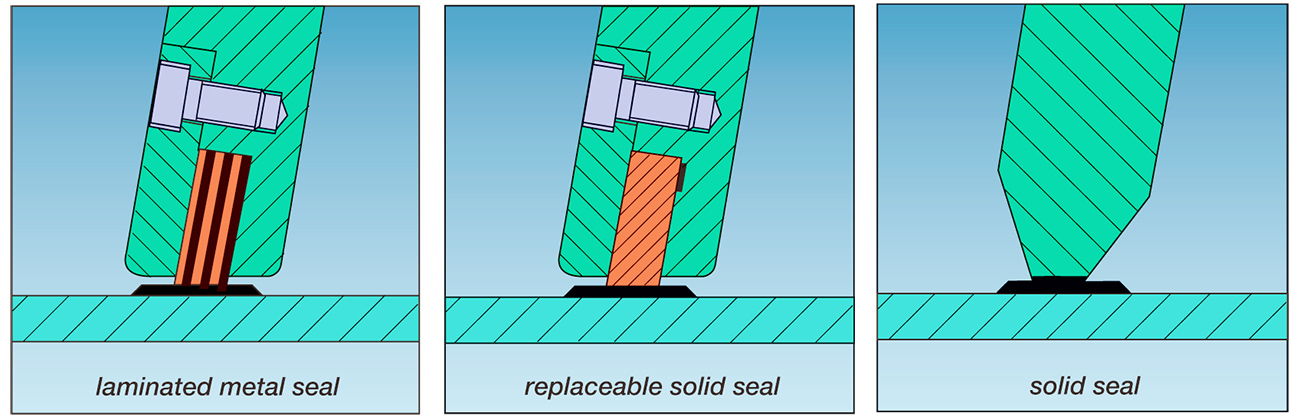

-- Laminated metal seal, replaceable solid seal, or solid seal are available to meet the requirements of various application.

-- Sealing surface overlay Cr-Ni alloy and finished to ensure sealing performance. As special request, stellite or other hard alloy can be used to enhance wear resistance and abrasion resistance.

-- Seat leakage rate achieves or better than API 598 & API 6D. Zero leakage is available as special request

-- The valves can be used in extensive working conditions and ensures long life. Meanwhile, there is no need to replace body, with low maintenance cost.

-- Integrated casting body and face - to - face dimensions conform to ISO 5752, ASME B16.10 and API 609.

-- Body with double flange ends. Wafer, lug, butt weld or special end connections ends are available.

-- Shafts sealed by resilient seal rings or stuffing boxes for in-service packing replacement.

-- The solid seal construction meets the requirements of inherent fire safe. Valve can comply with API 607

-- High temperature compatibility

-- Suitable for high cycle operation

-- Operation mode: Manual, electric, pneumatic, hydraulic etc.

General Application

● Petroleum and natural gas processing

● District heating

● Water treatment plant and supply system

● Chemicals and chemical plant

● Desalination plant

● Oil refining

● Power plant

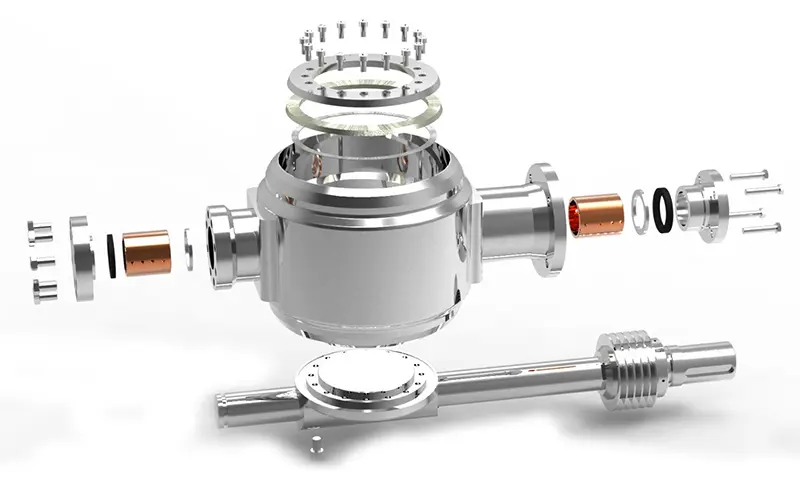

Materials of component

|

No |

Name |

Carbon steel |

Stainless steel |

Alloy steel |

|

1 |

Body |

ASTM A216 WCB |

ASTM A351 CF8M |

ASTM A217 WC6 |

|

2 |

Seat |

Stainless steel / hard alloy |

Stainless steel / hard alloy |

Stainless steel / hard alloy |

|

3 |

Disc |

ASTM A216 WCB |

ASTM A351 CF8M |

ASTM A217 WC6 |

|

4 |

Stem |

13% Cr |

17-4 PH / S31803 |

13% Cr |

|

5 |

Spiral wound gasket |

316SS+ graphite |

316SS+ graphite |

316SS+graphite |

|

6 |

Seal ring |

S31803+ graphite |

S31803+ graphite |

S31803+ graphite |

|

7 |

Retainer ring |

Carbon steel |

SS 316 |

Carbon steel |

|

8 |

Key |

ASTM A276 410 |

ASTM A182 F316 |

ASTM A276 410 |

|

9 |

Pin |

ASTM A276 410 |

ASTM A182 F316 |

ASTM A276 410 |

|

10 |

Flange gland |

ASTM A276 410 |

ASTM A182 F316 |

ASTM A276 410 |

|

11 |

Packing |

Graphite |

Graphite |

Graphite |

|

12 |

Spacer |

ASTM A276 410 |

ASTM A182 F316 |

ASTM A276 410 |

|

13 |

Bushing |

ASTM A276316 |

ASTM A276 316 |

ASTM A276 316 |

|

14 |

Dust ring |

Graphite |

Graphite |

Graphite |

|

15 |

Bearing washer |

ASTM A276 316 |

ASTM A276 316 |

ASTM A276 316 |

|

16 |

Thrust bearing |

ASTM A276 316 |

ASTM A276 316 |

ASTM A276 316 |

|

17 |

Spacer collar |

ASTM A276410 |

ASTM A182 F316 |

ASTM A276 410 |

|

18 |

Bottom wound gasket |

316SS+ graphite |

316SS + graphite |

316SS+graphite |

|

19 |

Bottom flange |

Carbon steel |

SS 316 |

Carbon steel |

|

20 |

York |

Q235 |

Q235 |

Q235 |

(Other materials are available on request.)

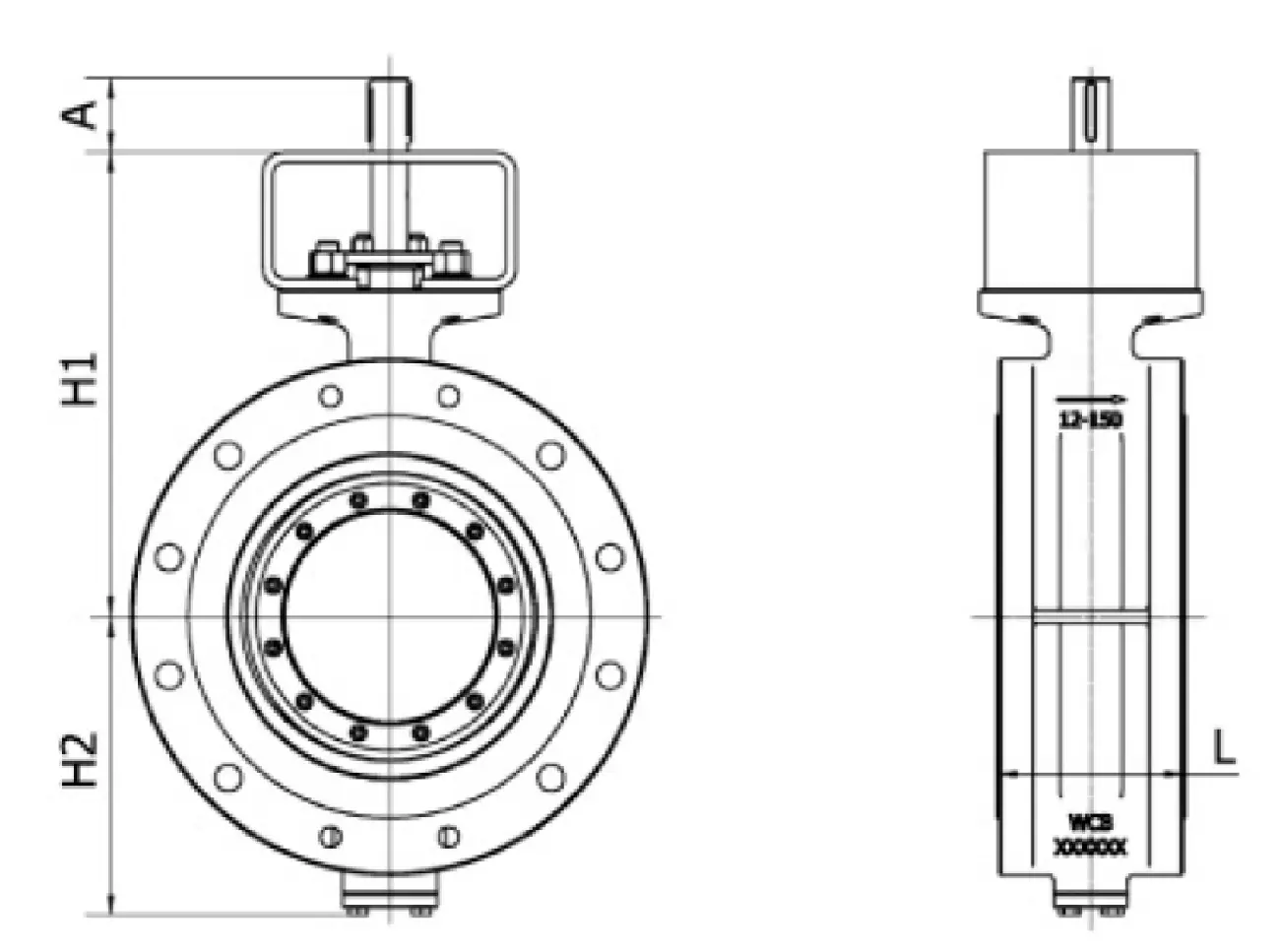

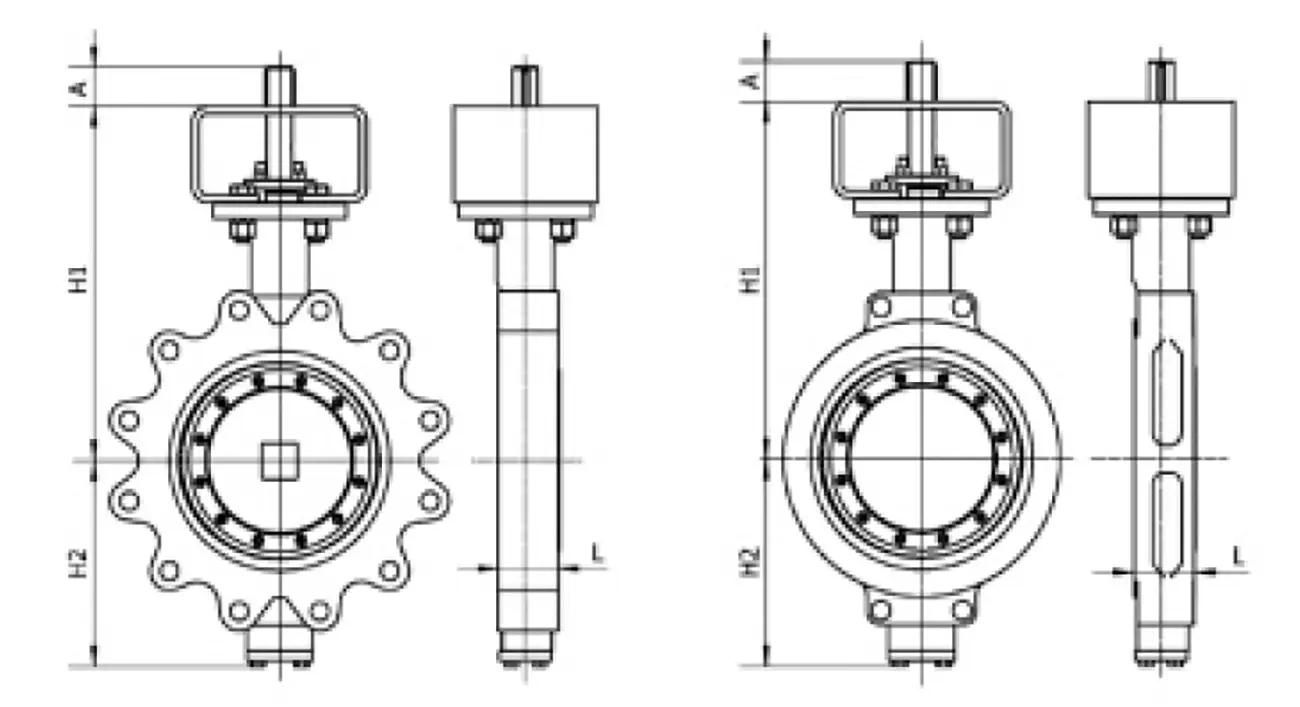

Dimensions

TRIPLE OFFSET METAL SEATED BUTTERFLY VALVEfor wafer & lug type

-All the outline dimensions and weight only for reference. If need, please contact us for exact data.

- Please contact us for other details or larger sizes.

|

Size |

Double Flange CL.150 |

Double Flange CL.300 |

|||||||||

|

inch |

mm |

H1 |

H2 |

A |

L |

Weight (kg) |

H1 |

H2 |

A |

L |

Weight (kg) |

|

6 |

150 |

330 |

165 |

40 |

140 |

40 |

350 |

189 |

40 |

140 |

61 |

|

8 |

200 |

385 |

214 |

40 |

152 |

61 |

415 |

236 |

56 |

152 |

86 |

|

10 |

250 |

425 |

243 |

40 |

165 |

83 |

455 |

272 |

56 |

165 |

100 |

|

12 |

300 |

490 |

286 |

56 |

178 |

127 |

490 |

310 |

80 |

178 |

175 |

|

14 |

350 |

525 |

312 |

56 |

190 |

166 |

545 |

335 |

80 |

190 |

284 |

|

16 |

400 |

545 |

350 |

80 |

216 |

198 |

575 |

389 |

140 |

216 |

340 |

|

18 |

450 |

580 |

383 |

80 |

222 |

229 |

660 |

422 |

140 |

222 |

487 |

|

20 |

500 |

580 |

414 |

80 |

229 |

311 |

700 |

462 |

140 |

229 |

529 |

|

24 |

600 |

690 |

484 |

140 |

267 |

433 |

785 |

531 |

160 |

267 |

834 |

|

28 |

700 |

795 |

556 |

140 |

292 |

702 |

880 |

617 |

160 |

292 |

1382 |

|

30 |

750 |

865 |

611 |

160 |

318 |

848 |

1000 |

671 |

180 |

318 |

1595 |

|

32 |

800 |

865 |

611 |

160 |

318 |

1015 |

1000 |

671 |

180 |

318 |

1805 |

|

36 |

900 |

1000 |

736 |

160 |

330 |

1495 |

1150 |

801 |

200 |

330 |

2215 |

|

40 |

1000 |

1130 |

801 |

180 |

410 |

2035 |

1150 |

801 |

200 |

410 |

2270 |

|

42 |

1050 |

1130 |

801 |

180 |

410 |

2155 |

1215 |

900 |

250 |

410 |

2756 |

|

48 |

1200 |

1267 |

866 |

200 |

470 |

3045 |

1300 |

991 |

280 |

470 |

3400 |

|

Size |

Double Flange CL.600 |

Double Flange CL.900 |

|||||||||

|

inch |

mm |

H1 |

185 |

A |

L |

Weight (kg) |

H1 |

H2 |

A |

L |

Weight (kg) |

|

6 |

150 |

355 |

238 |

56 |

210 |

121 |

355 |

238 |

56 |

225 |

167 |

|

8 |

200 |

405 |

263 |

80 |

230 |

198 |

466 |

293 |

80 |

275 |

297 |

|

10 |

250 |

485 |

328 |

140 |

250 |

298 |

520 |

345 |

140 |

325 |

385 |

|

12 |

300 |

538 |

365 |

140 |

270 |

378 |

620 |

378 |

160 |

375 |

588 |

|

14 |

350 |

610 |

390 |

140 |

290 |

445 |

683 |

456 |

160 |

425 |

795 |

|

16 |

400 |

680 |

440 |

160 |

310 |

670 |

730 |

492 |

160 |

475 |

1219 |

|

18 |

450 |

683 |

460 |

160 |

330 |

750 |

770 |

510 |

200 |

500 |

1441 |

|

20 |

500 |

195 |

526 |

200 |

350 |

1000 |

870 |

590 |

200 |

575 |

1924 |

|

24 |

600 |

885 |

623 |

200 |

390 |

1452 |

1020 |

673 |

200 |

675 |

2841 |

-All the outline dimensions and weight only for reference. If need, please contact us for exact data.

- Please contact us for other details or larger sizes.

|

Size |

Lug Type CL.150 |

Lug Type CL.300 |

|||||||||

|

inch |

mm |

H1 |

H2 |

A |

L |

Weight (kg) |

H1 |

H2 |

A |

L |

Weight (kg) |

|

6 |

150 |

330 |

165 |

40 |

57 |

23 |

350 |

189 |

40 |

59 |

41 |

|

8 |

200 |

385 |

214 |

40 |

64 |

36 |

415 |

236 |

56 |

73 |

56 |

|

10 |

250 |

425 |

243 |

40 |

71 |

49 |

455 |

272 |

56 |

83 |

77 |

|

12 |

300 |

490 |

286 |

56 |

81 |

83 |

490 |

310 |

80 |

92 |

119 |

|

14 |

350 |

525 |

312 |

56 |

92 |

117 |

545 |

335 |

80 |

117 |

254 |

|

16 |

400 |

545 |

350 |

80 |

102 |

160 |

575 |

389 |

140 |

133 |

300 |

|

18 |

450 |

580 |

383 |

80 |

114 |

194 |

660 |

422 |

140 |

149 |

455 |

|

20 |

500 |

580 |

414 |

80 |

127 |

270 |

700 |

462 |

140 |

159 |

499 |

|

24 |

600 |

690 |

484 |

140 |

154 |

387 |

785 |

531 |

160 |

181 |

788 |

|

28 |

700 |

795 |

556 |

140 |

165 |

614 |

|||||

|

30 |

750 |

865 |

611 |

160 |

190 |

678 |

|||||

|

32 |

800 |

865 |

611 |

160 |

190 |

801 |

|||||

|

36 |

900 |

1000 |

736 |

160 |

203 |

1015 |

|||||

|

40 |

1000 |

1130 |

801 |

180 |

216 |

1590 |

|||||

|

42 |

1050 |

1130 |

801 |

180 |

216 |

1802 |

|||||

|

48 |

1200 |

1267 |

866 |

200 |

254 |

2284 |

|||||

|

Size |

Wafer Type CL.150 |

Wafer Type CL.300 |

|||||||||

|

inch |

mm |

H1 |

185 |

A |

L |

Weight (kg) |

H1 |

H2 |

A |

L |

Weight (kg) |

|

6 |

150 |

330 |

165 |

40 |

57 |

20 |

350 |

189 |

40 |

59 |

29 |

|

8 |

200 |

385 |

214 |

40 |

64 |

34 |

415 |

236 |

56 |

73 |

50 |

|

10 |

250 |

425 |

243 |

40 |

71 |

45 |

455 |

272 |

56 |

83 |

75 |

|

12 |

300 |

490 |

286 |

56 |

81 |

73 |

490 |

310 |

80 |

92 |

109 |

|

14 |

350 |

525 |

312 |

56 |

92 |

97 |

545 |

335 |

80 |

117 |

164 |

|

16 |

400 |

545 |

350 |

80 |

102 |

123 |

575 |

389 |

140 |

133 |

228 |

|

18 |

450 |

580 |

383 |

80 |

114 |

164 |

660 |

422 |

140 |

149 |

285 |

|

20 |

500 |

580 |

414 |

80 |

127 |

220 |

700 |

462 |

140 |

159 |

343 |

|

24 |

600 |

690 |

484 |

140 |

154 |

324 |

785 |

531 |

160 |

181 |

513 |

|

28 |

700 |

795 |

556 |

140 |

165 |

537 |

|||||

|

30 |

750 |

865 |

611 |

160 |

190 |

594 |

|||||

|

32 |

800 |

865 |

611 |

160 |

190 |

650 |

|||||

|

36 |

900 |

1000 |

736 |

160 |

203 |

746 |

|||||

|

40 |

1000 |

1130 |

801 |

180 |

216 |

1172 |

|||||

|

42 |

1050 |

1130 |

801 |

180 |

216 |

1380 |

|||||

|

48 |

1200 |

1267 |

866 |

200 |

254 |

1860 |

|||||

Please contact us for the details of other or larger sizes.

Product Display